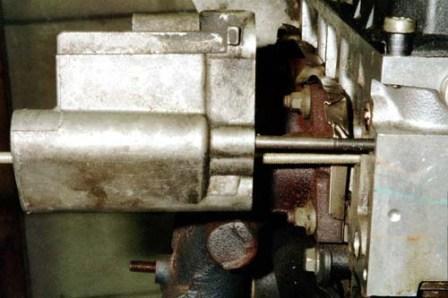

The engine is from Renault a K7M from a Renault Megane/Scenic I discovered that the flywheel house from a V340 fits to the engine and that was a good base to go on further.

What I did not know at that time, was that also the flywheel from a V340 fits to the crank, So I started to modify the K7M flywheel to adapt the V340 clutch .but that was no success, the starter motor did not fit to the bell house and the starter gear hits the bell house too..

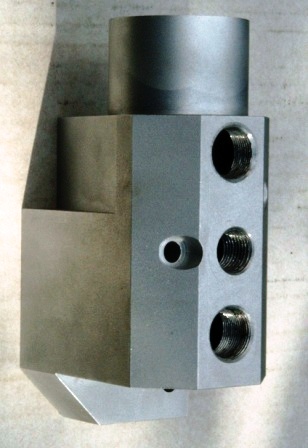

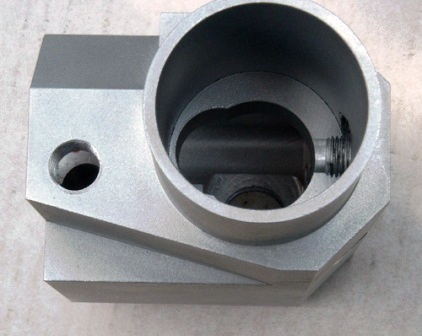

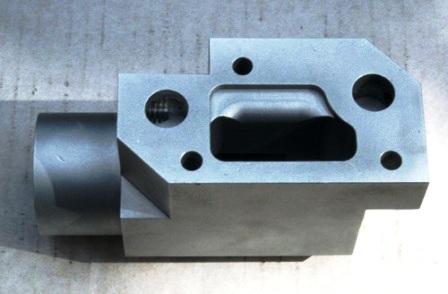

Another big problem , and I guess, the main problem was the thermostat house. As it is factory fits to the engine by Renault, in the Daf 66 it will hit the tie rod and the water outlet focused to the wrong side Made an adapter for 180 degree turn and also to get the thermostat house higher from the engine. Otherwise it would hit again by the tie rod . The problem with that thermostat house is the fact that it also has 2 oil canals too ??.

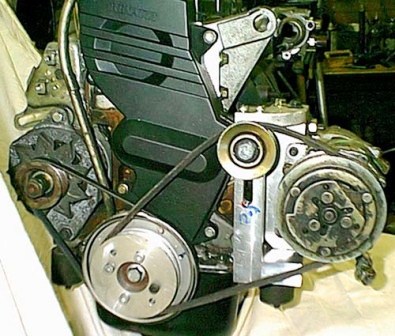

All other modifications are simple jobs to do. Left front of the engine added an aluminum bar for the motor mount and a base for the A/C pump. At the R front just enough room along the case for a motor mount just like a B14. Basically the K7M is about 15 mm longer as a B14 but it did not fit in the standard front barrier , oil pan it too wide, so a new barrier had to be made Again mechanical modifications where no problem at all. and simple to do.

BUT these new Renault ECU's have a start lock. and for that reason the project had a delay of about a year. Tried all different ways to get that damned ECU unlocked, but no success.

|

|

|

|

|

|

|

|

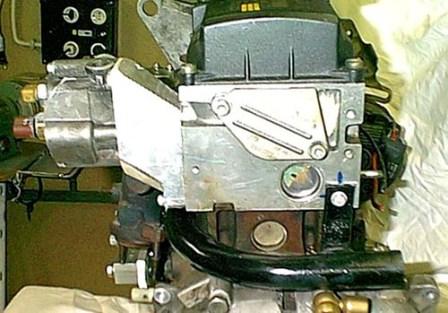

| After more than a year

struggling with the ECU, I decided to

say goodbye to the injection system, and moved to carburetors .A

Clio intake manifold fits to the head only an adapter plate

between head and manifold has to be made, also an adapter

between intake and carburetor is needed because the Clio

manifold is on a 15 degree angle.

|

|

|

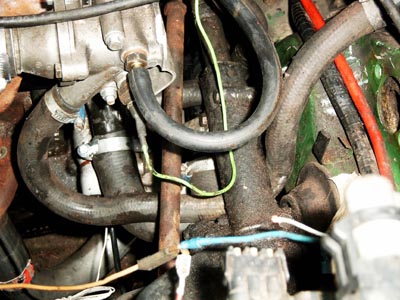

| The next problem was the ignition, but this was also not so complicated as I thought. Again a Clio part fits perfectly, only a minor modification has to be made to the distributor cap., The Clio cap with the straight cable outlets hits the heather cover, I discovered that a cap from a Peugeot with side outlet fits, but now the rotor and rotor shaft were too long, - 8 mm. - After shorten the shaft and rotor this problem was also be solved. |

|

|

|

|

|

|

|

|

|

|

|

|

After I had the engine in a parts car, for a test , some more modifications showed up. I know the steering gear and tie rods are an obstacle for bigger engines. When it was in the car , in my opinion there was too less clearance between thermostat house and tie rods I wanted more clearance, and that meant that the engine has to be moved forwards for about 15 mm. But how to do this ?? I did not want to move, or modify the rear engine bearer so I decided to ad a piece of aluminum - 7 mm - thick at both ends of the rear motor mounts. Special made nuts were necessary to connect the motor mounts to the bell house and connection plate. Not enough thread left for an ordinary nut.

When you want more power in your Daf 66. I think this is a better option as a Renault Alpine engine. This transplant is much easier to do, and the HP output and torque is more powerful as from an Alpine.

A dream came through

Since I have the V340 cvt transmission in my 66, I wanted to make it possible to change the clutch without to take the engine out, just like a V340 I can remove the drive shaft , just like a V340, but could not take the bell house off.. I had the solution for this in my head for years , but I never got the final push to make it ., was also afraid to do this. But now together with this engine job I also modified the rear engine bearer, that means I can take it out, and so the bell house.

|

|

|

|

|

|

The thermostat house is a big problem and also complicated. So I decided to design a new and simple new thing. AND HER IT IS.

11-11-2004 |

|

|

|

|

|

|

|

|

|

|

||

|

||

For more photo's Fotoalbum daf - Daf changes made by Matt/XP-1600

08-09-2005